旋流塔(Cyclone Tower)是一种常用于气体净化、除尘或气液分离的环保设备,结合了旋风分离器和喷淋塔的特点,通过旋转气流和液体喷淋的协同作用去除颗粒物或有害气体。以下是关于旋流塔的详细介绍:

1. 工作原理

• 旋转气流:污染气体从塔体切向进入,形成高速旋转的涡流,离心力使颗粒物甩向塔壁,与壁面碰撞后失去动能,落入底部集尘区。

• 喷淋洗涤:顶部喷淋系统向下喷洒吸收液(如水或化学溶液),与旋转气流充分接触,进一步捕捉细小颗粒或吸收气态污染物(如SO₂、HCl等)。

• 气液分离:净化后的气体经除雾器去除液滴后从顶部排出,液体则循环使用或处理后排放。

2. 主要结构

• 塔体:通常为立式圆筒形,材质可选PP(聚丙烯)、FRP(玻璃钢)或碳钢衬胶。

• 进气口:切向设计,形成旋流。

• 喷淋层:多级喷嘴均匀分布,增强气液接触。

• 除雾器:位于顶部,减少气体带液。

• 底部锥斗:收集分离的颗粒物和液体。

3. 技术特点

• 高效除尘:可处理1–10μm的颗粒,效率达90%以上(配合喷淋时更高)。

• 气液双效:兼具除尘和废气吸收功能,适用于复合污染。

• 低阻节能:相比传统湿式 scrubber,压降较低。

• 适应性强:可处理高温、高湿或腐蚀性气体。

4. 应用领域

• 工业除尘:冶金、建材、化工等行业的粉尘治理。

• 废气处理:酸雾、碱雾、有机废气(需配合化学吸收剂)。

• 预处理:作为布袋除尘或电除尘的前置设备,减轻负荷。

5. 优缺点

优点:

• 结构简单,维护方便。

• 运行成本低,无移动部件。

• 可处理高浓度粉尘。

缺点:

• 对亚微米级颗粒(<1μm)效率有限。

• 耗水量较大,需处理废水。

6. 设计要点

• 空塔气速:通常3–5 m/s,过高易导致带液。

• 液气比(L/G):一般0.5–3 L/m³,根据污染物浓度调整。

• 旋流板角度:影响气流旋转强度,需优化设计。

7. 维护与优化

• 定期清理底部沉积物,防止堵塞。

• 检查喷嘴磨损,确保雾化效果。

• 监测压差变化,判断系统运行状态。

8. 与其他设备的对比

• vs 普通旋风分离器:旋流塔因加入喷淋,对细小颗粒和可溶性气体效果更佳。

• vs 文丘里洗涤器:能耗更低,但文丘里对微细颗粒捕集效率更高。

浏览人数

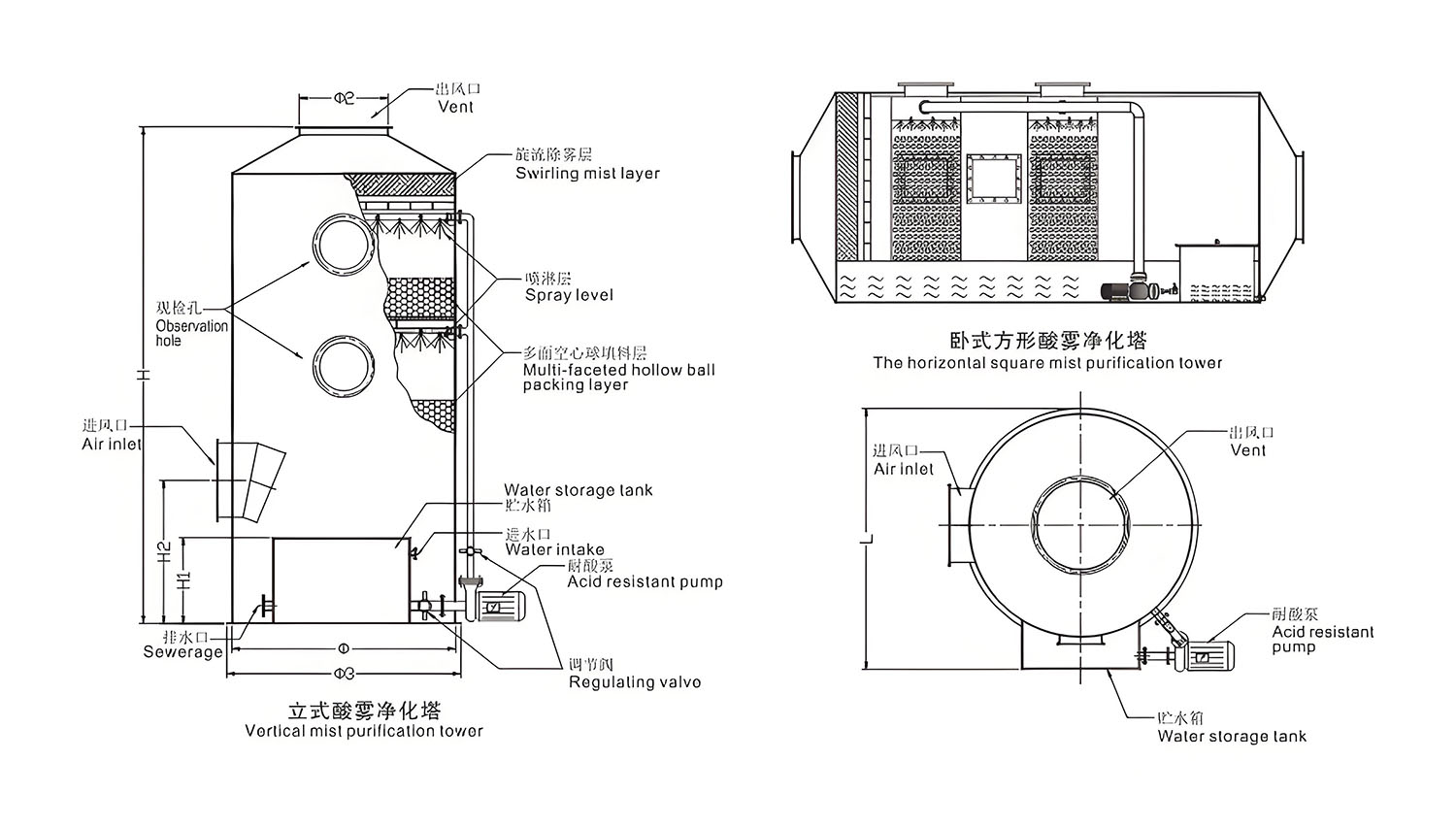

旋流塔 设备原理:对于腐蚀性气体(如酸、碱性废气)的治理,目前多采用液体吸收法治理。采用液体吸收法治理该废气,关键在于净化设备的选择。目前,我公司自主开发了净化效率高、操作管理简单、使用寿命长的酸、碱性废气净化工艺与设备。该工艺与产品具有结构简单、能耗低、净化效率高和适用范围广的特点,能有效去除氯化氢气体(HCl)、氟化氢气体(HF)、氨气(NH3)、硫酸雾(H₂SO。)、铬酸雾(CrO,)、氰氢酸气体(HCN)、碱蒸气(NaOH)、硫化氢气体(H2S)、福尔马林(HCHO)等水溶性气体。酸雾废气由风管引入净化塔,经过填料层,废气与氢氧化钠吸收液进行气液两相充分接触吸收中和反应,酸雾废气经过净化后,再经除雾板脱水除雾后由风机排入大气。吸收液在塔底经水泵增压后在塔顶喷淋而下,最后回流至塔底循环使用。净化后的酸雾废气达到广东省地方排放标准的排放要求,低于国家排放标准。

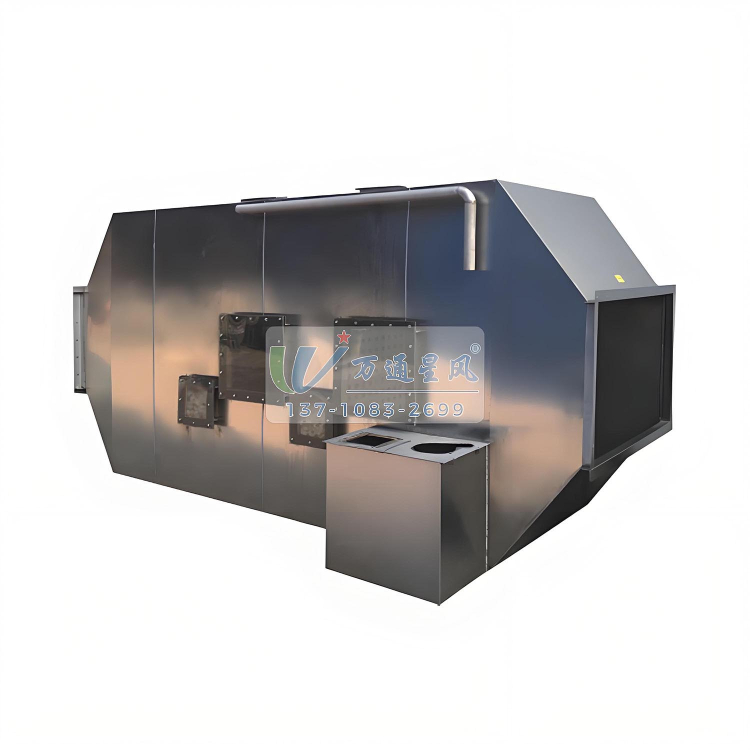

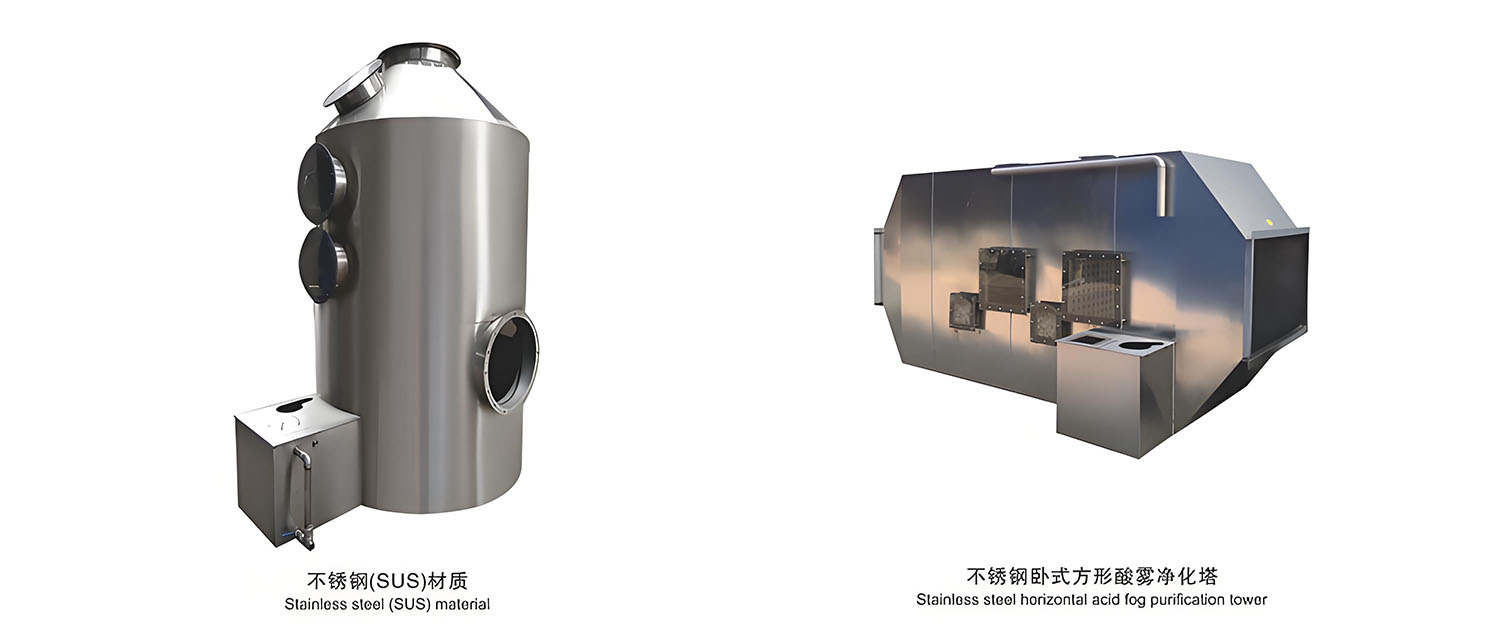

设备特点: 本设备采用填料塔对废气进行净化,适合于连续和间歇排放废气的治理;工艺简单,管理、操作及维修相当方便简洁,不会对车间的生产造成任何影响;适用范围广,可同时净化多种污染物;压降较低,操作弹性大,且具有很好的除雾性能;塔体可根据实际情况采用玻璃钢/不锈钢/PP塑料/PVC塑料材料制作;填料采用高效、低阻的鲍尔环,可彻底地去除气体中的异味、有害物质等。

结构形式: 本设备分单塔体和双塔体。采用圆形塔体,用法兰分段联接而成。具体由贮液箱、塔体、进风段、喷淋层、填料层、旋流除雾层、出风锥帽、观检孔等组成。

产品用途: 本设备可广泛应用于化工、电子、冶金、电镀、纺织(化纤)、食品、机械制造等行业过程中排放的酸、碱性废气的净化处理。如调味食品、制酸、酸洗、电镀、电解、蓄电池等。

Cyclone tower Principle of equipment: For the treatment of corrosive gases (such as acid and alkaline waste gas) liquid absorption method is mostly used at present. Using liquid absorption to treat the waste gas is the key to the selection of purification equipment. At present our company has independently developed acid and alkaline waste gas purification process and equipment with high purification efficiency simple operation and management and long service life. The process and products have the characteristics of simple structure low energy consumption high purification efficiency and wide application range can effectively remove hydrogen chloride gas (HCl) hydrogen fluoride gas (HF) ammonia gas (NH3) sulfuric acid fog (H₂SO). Chromic acid mist (CrO,) cyanuric acid gas (HCN) alkali vapor (NaOH) hydrogen sulfide gas (H2S) formalin (HCHO) and other water-soluble gas. Acid fog exhaust gas is introduced into the purification tower by the air duct and through the packing layer the exhaust gas and sodium hydroxide absorption liquid are fully contacted absorbed and neutralized. After purification the acid fog exhaust gas is dehydrated and defogged by the defogging plate and discharged into the atmosphere by the fan. The absorption liquid is pressurized by the pump at the bottom of the tower and sprayed down at the top of the tower and finally returned to the bottom of the tower for recycling. The purified acid fog exhaust gas meets the emission requirements of Guangdong provincial emission standards lower than the national emission standards.

Equipment features:The equipment uses packed tower to purify the exhaust gas suitable for continuous and intermittent exhaust gas treatment; Simple process management operation and maintenance is quite convenient and simple will not cause any impact on the production of the workshop; Wide range of application can simultaneously purify a variety of pollutants; Low pressure drop large operation elasticity and has good defogging performance; The tower body can be made of FRP/stainless steel /PP plastic /PVC plastic material according to the actual situation; The packing uses the Pall ring with high efficiency and low resistance which can completely remove the odor and harmful substances in the gas

Structure form:The equipment is divided into single tower body and double tower body. The circular tower body is connected with flange segments. It is composed of liquid storage tank tower body air inlet section spray layer packing layer cyclone defogging layer air cone cap inspection hole and so on

Product use:This equipment can be widely used in chemical industry electronics metallurgy electroplating textile (chemical fiber) food machinery manufacturing and other industries in the process of acid alkaline waste gas purification treatment. Such as flavoring food acid pickling electroplating electrolysis battery and so on

| 型 号 | ||||||||

|---|---|---|---|---|---|---|---|---|

|

设计风量 (M3/h) |

配用风机 型号(No) |

配用风机 功率(Kw) |

配用风机 风量(M3/h) |

配用风机 全压(Pa) |

配用耐酸水泵 型号(No) |

配用耐酸水泵 功率(KW) |

配用耐酸水泵 风量(M3/h) |

|

| BJT-650 | 1500 | F4-72-3.6A | 1.1 | 1332-2634 | Y2-801-2 | 0.75 | 9 | |

| BJT-800 | 3000 | F4-72-4.5A | 1.1 | 2712-5084 | Y90S-2 | 1.5 | 12 | |

| BJT-1000 | 5000 | F4-72-5A | 2.2 | 4096-6952 | Y90S-2 | 1.5 | 12 | |

| BJT-1200 | 8000 | F4-72-6A | 4 | 6291-14124 | Y2-90L-2 | 2.2 | 24 | |

| BJT-1400 | 10000 | F4-72-6C | 5.5 | 8288-16575 | Y2-90L-2 | 2.2 | 24 | |

| BJT-1500 | 13000 | F4-72-6C | 11 | 12000-15890 | Y2-90L-2 | 2.2 | 24 | |

| BJT-1650 | 15000 | F4-72-8C | 7.5 | 12224-16705 | 1209-1166 | Y2-112M-2 | 4 | 33 |

| BJT-2000 | 20000 | F4-72-10C | 11 | 22312-31230 | Y2-112M-2 | 4 | 33 | |

| BJT-2400 | 24000 | F4-72-10C | 15 | 25100-34000 | Y2-112M-2 | 4 | 33 | |

| BJT-3000 | 30000 | F4-72-12C | 18.5 | 28170-37000 | 850-720 | Y2-112M-2 | 5.5 | 39 |

| BJT-3500 | 35000 | F4-72-12C | 30 | 34218-47800 | 1090-850 | Y2-132S2-2 | 7.5 | 37 |

| 酸雾初试浓度 | HCL<1000mg/m3 | 净化效率 | 95~99% |

|---|---|---|---|

| H2SO4<1000mg/m3 | 92~98% | ||

| NH3<100mg/m3 | 95% | ||

| HCN<100mg/m3 | 90~95% | ||

| CrO3<500mg/m3 | 92~98% |

| 注:以上性能仅供参考,不作客户实际操作使用。 | 客户如需增加净化效率可增高塔体、增加喷淋、净化层,详细请与我司联络。 |

|---|---|

| 中和液NaOH溶液尝试 | 2-6% |

| 净化塔阻力(Pa) | 400 |

外形及安装尺寸示意图 Lnstallation size diagram

|

型号 外观尺寸 |

|||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| BJT650 | BJT800 | BJT1000 | BJT1200 | BJT1400 | BJT1500 | BJT1650 | BJT2000 | BJT2400 | BJT3000 | BJT3500 | |

| ø | 650 | 800 | 1000 | 1200 | 1400 | 1500 | 1650 | 2000 | 2400 | 3000 | 3500 |

| ø1 | 300 | 350 | 400 | 400 | 500 | 500 | 600 | 800 | 800 | 1000 | 1200 |

| ø2 | 300 | 350 | 400 | 400 | 500 | 500 | 600 | 800 | 800 | 1000 | 1200 |

| ø3 | 750 | 900 | 1100 | 1300 | 1500 | 1600 | 1750 | 2100 | 2500 | 3100 | 3600 |

| H | 3000 | 3100 | 3600 | 3900 | 3900 | 3900 | 4200 | 4800 | 5400 | 6000 | 6000 |

| H1 | 500 | 500 | 600 | 600 | 600 | 600 | 600 | 600 | 800 | 800 | 800 |

| H2 | 750 | 800 | 900 | 900 | 1000 | 1000 | 1200 | 1300 | 1500 | 1500 | 1800 |

| L | 1000 | 1200 | 1600 | 1800 | 2000 | 2000 | 2200 | 2800 | 3200 | 3800 | 4300 |

品牌:万通星风 品名:旋流塔 型号: 简介:系统之风机组将收集到的废气吸入酸雾洗涤塔内,流经填充层段(气/液接触反应之介质),让废气与填充物表面流动的药液(洗涤液)充分接触,以吸附废气中所含的酸性或碱性污物。