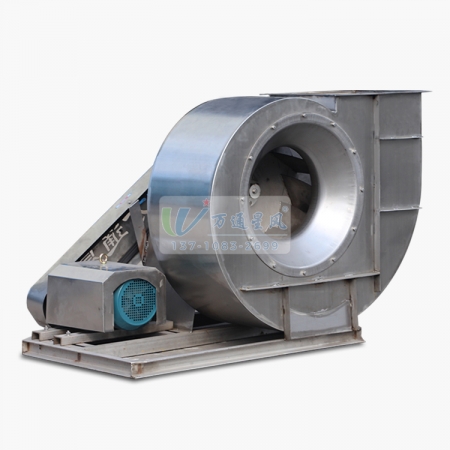

4-72型-C式鄄城不锈钢离心风机是指风机的叶轮、外壳及其他与介质接触的零部件采用不锈钢制造的离心风机。不锈钢离心风机具有优良的耐腐蚀性、防锈性和耐高温性能,广泛应用于化工、医药、食品等行业中对洁净度、卫生要求较高的场合。同时,不锈钢离心风机还具有结构紧凑、噪音低、效率高等特点。

浏览人数

4-72C型不锈钢离心风机

4-72C型不锈钢离心风机可输送空气和其它不自燃的、对人体无害的、对钢材无腐蚀性的气体。气体内不允许有粘性物质,所含尘土及硬质颗粒物不大于150mg/m3。气体温度不得超过80℃该风机广泛适用于工矿企业、大型建筑物、宾馆酒楼等室内通风换气排烟。

产品型式:该风机为C式传动:风机叶轮悬臂支承,带轮在两轴承之外的V型带传动。机号有NO2.8、3.2、3.6、4、4.5、5、5.6、6、6.3、7.1、8、10、12十三种。可制成右旋和左旋两种型式,叶轮顺时针旋转,称为右旋风机。以“右”表示,叶轮逆时针旋转,称为左旋风机,以“左”表示。风机的出口位置,以机壳的出风角度表示。4-72NO2.8-10出厂时均做成多种型式,可根据使用单位要求安装成所需的位置,即出风口位置调整范围0°~225°间隔是22.5°或45°,即(0°、45°、90°、135°、180°、225°;)共六种,用户根据需求制成一种方向角度。

结构特点:本风机主要由叶轮、机壳、进风口、机架、轴承箱等皮带传动而组成。叶轮:由10个后倾斜的机翼型叶片、曲线型前盘和平板后盘组成。并经过动平衡校正,气动性能,故运转平衡、振动小、效率高、寿命长等特点。机壳:用钢板焊成蜗型壳体。进风口:制成整体(全部模具成型),装于风机的侧面,于轴向平行的戴面未曲线形状,能使气体顺利进入叶轮,且损失较小。传动组:由主轴、轴承箱、联轴器等。主轴由优质钢制成,轴承箱整体结构,采用滚动轴承,分为水冷和油冷两种。

4-72C Stainless steel centrifugal fan

4-72C Stainless steel centrifugal fan It can transport air and other non-flammable harmless to human body and non-corrosive gas to steel. No viscous substances are allowed in the gas and the dust and hard particles are not more than 150mg/m3. The air temperature shall not exceed 80℃. The fan is widely used for indoor ventilation and smoke extraction in industrial and mining enterprises large buildings hotels and restaurants.

Product type: The fan is C-type drive: the fan impeller is cantilever supported and the belt wheel is V-type drive outside the two bearings. There are 13 kinds of machine numbers: NO2.8, 3.2, 3.6, 4, 4.5, 5, 5.6, 6, 6.3, 7.1, 8, 10 and 12. Can be made into right-handed and left-handed two types the impeller rotating clockwise called right-handed fan. In & other; Right & throughout; That the impeller rotates counterclockwise called the left cyclone to “ Left & throughout; Said. The outlet position of the fan is expressed by the outlet Angle of the enclosure. 4-72no2.8-10 factory are made into a variety of types according to the requirements of the unit installed into the required position that is the outlet position adjustment range of 0°~225° interval is 22.5° or 45° that is (0°, 45°, 90°, 135°, 180°, 225°) A total of six kinds the user according to the demand to make a direction Angle.

Structural features: The fan is mainly composed of impeller housing air intake frame bearing box and other belt drive. Impeller: consists of 10 rear sloped airfoil blades curved front disc and flat rear disc. And after dynamic balance correction pneumatic performance so the operation balance small vibration high efficiency long life and other characteristics. Housing: welded with steel plate into a cochlear housing. Air INLET: MADE INTO a WHOLE (all mold molding) installed on the side of the fan parallel to the axial surface without curve shape can make the gas smoothly into the impeller and the loss is small. Transmission group: spindle bearing box coupling etc. The main shaft is made of high quality steel. The overall structure of the bearing box is made of rolling bearings which are divided into water cooled and oil cooled.

| 机 号 Model(NO) |

|||||

|---|---|---|---|---|---|

| 转 速 Speed(r/min) |

功 率 Power(KW) |

机座号 Poles frame size-p |

流 量 Volume(M3/h) |

全 压 Total pressure(pa) |

|

| 2.8C | 2600 | 0.75-2 | Y80M-2 | 1174-1800 | 776-619 |

| 2200 | 0.37-2 | Y71M-2 | 994-1522 | 556-443 | |

| 1800 | 0.25-2 | Y63M-2 | 813-1245 | 372-296 | |

| 3.2C | 2600 | 1.1-2 | Y80M-2 | 1753-2686 | 1015-808 |

| 2200 | 0.75-2 | Y80M-2 | 1483-2273 | 726-579 | |

| 1800 | 0.55-2 | Y71M-2 | 1213-1860 | 486-387 | |

| 3.6C | 2600 | 2.2-2 | Y90L-2 | 2730-4085 | 1230-1009 |

| 2200 | 1.5-2 | Y90S-2 | 2310-3434 | 881-723 | |

| 1800 | 0.75-2 | Y80M-2 | 1890-2810 | 590-483 | |

| 4C | 2600 | 3.0-2 | Y100L-2 | 4040-5345 | 1582-1384 |

| 2300 | 2.2-2 | Y90L-2 | 3573-5491 | 1238-917 | |

| 2000 | 1.5-2 | Y90S-2 | 3107-4775 | 936-694 | |

| 1700 | 1.1-2 | Y80M-2 | 2641-4058 | 676-501 | |

| 4.5C | 2600 | 5.5-2 | Y132S-2 | 5752-8839 | 2007-1486 |

| 2300 | 4.0-2 | Y112M-2 | 5088-7819 | 1570-1163 | |

| 2000 | 3.0-2 | Y100M-2 | 4428-6788 | 1187-879 | |

| 1700 | 2.2-2 | Y90M-2 | 3761-5779 | 858-635 | |

| 5C | 2600 | 11.0-2 | Y160M-2 | 7938-12845 | 2527-1876 |

| 2300 | 7.5-2 | Y132S-2 | 7022-11363 | 1978-1468 | |

| 2000 | 5.5-2 | Y132S-2 | 6106-9881 | 1495-1110 | |

| 1700 | 3.0-2 | Y100L-2 | 5190-8399 | 1080-802 | |

| 5.6C | 2600 | 15.0-2 | Y160M-2 | 9734-19466 | 3213-2035 |

| 2300 | 11.0-2 | Y160M-2 | 8610-17220 | 2514-1593 | |

| 2000 | 7.5-2 | Y132S-2 | 7487-14974 | 1901-1204 | |

| 1700 | 5.5-4 | Y132S-4 | 6364-12728 | 1373-870 | |

| 1400 | 3.0-4 | Y100M-4 | 5242-10482 | 937-590 | |

| 6C | 2240 | 15.0-2 | Y160M-2 | 10314-20628 | 2734-1733 |

| 2000 | 11.0-2 | Y160M-2 | 9209-18418 | 2176-1380 | |

| 1800 | 7.5-4 | Y132M-4 | 8288-16576 | 1790-1116 | |

| 1600 | 5.5-4 | Y132S-4 | 7367-14734 | 1689-881 | |

| 1250 | 3.0-4 | Y100L-4 | 5756-11511 | 846-537 | |

| 1120 | 2.2-4 | Y100L-4 | 5157-10314 | 679-431 | |

| 900 | 1.5-4 | Y90L-4 | 4144-8288 | 438-278 | |

| 800 | 1.1-4 | Y90S-4 | 3684-7367 | 346-220 | |

| 6.3C | 2200 | 18.5-2 | Y160L-2 | 15342-21474 | 2908-2303 |

| 1900 | 11.0-2 | Y160M-2 | 13250-18546 | 2169-1718 | |

| 1600 | 7.5-2 | Y132S-2 | 11158-15618 | 1538-1218 | |

| 1300 | 4.0-4 | Y112M-4 | 9066-12689 | 1015-804 | |

| 1000 | 2.2-4 | Y100L-4 | 6793-9761 | 600-475 | |

| 700 | 0.75-4 | Y80M-4 | 4881-6833 | 294-233 | |

| 7.1C | 1800 | 18.5-4 | Y180M-4 | 15736-25265 | 2422-1801 |

| 1600 | 15.0-4 | Y160L-4 | 13987-22635 | 1914-1423 | |

| 1450 | 11.0-4 | Y160M-4 | 12676-20513 | 1572-1168 | |

| 1200 | 5.5-4 | Y112M-4 | 10490-16976 | 1076-800 | |

| 960 | 3.0-4 | Y100L-4 | 8392-13581 | 689-512 | |

| 700 | 1.5-4 | Y160L-4 | 6119-9903 | 366-272 | |

| 8C | 1800 | 30.0-2 | Y200L-2 | 8392-13581 | 689-512 |

| 1800 | 37.0-2 | Y200L-2 | 28105-36427 | 2920-2302 | |

| 1600 | 22.0-2 | Y180M-2 | 17463-22435 | 2478-2390 | |

| 1600 | 30.0-2 | Y160L-2 | 24982-32380 | 2303-1816 | |

| 1250 | 11.0-4 | Y160M-4 | 13643-25297 | 1507-1106 | |

| 1120 | 7.5-4 | Y132M-4 | 1224-15705 | 1209-1166 | |

| 1120 | 11.0-4 | Y60M-4 | 17487-22666 | 1124-887 | |

| 1000 | 5.5-4 | Y112M-4 | 10914-14022 | 963-929 | |

| 1000 | 7.5-4 | Y132M-4 | 15614-20237 | 895-707 | |

| 900 | 4.0-4 | Y112M-4 | 9823-12620 | 779-752 | |

| 900 | 5.5-4 | Y112M-4 | 14052-18213 | 725-572 | |

| 800 | 3.0-4 | Y100L-4 | 8732-16190 | 615-452 | |

| 710 | 3.0-4 | Y100L-4 | 7749-14368 | 485-356 | |

| 10C | 1250 | 37.0-4 | Y225S-4 | 34863-48797 | 2373-1877 |

| 1120 | 30.0-4 | Y200L-4 | 31237-43722 | 1902-1505 | |

| 1000 | 18.5-4 | Y180M-4 | 27890-39038 | 1514-1199 | |

| 900 | 15.0-4 | Y160L-4 | 25101-35134 | 1225-970 | |

| 800 | 11.0-4 | Y160M-4 | 22312-31230 | 967-766 | |

| 710 | 7.5-4 | Y132M-4 | 19802-27717 | 791-603 | |

| 630 | 5.5-4 | Y112M-4 | 17571-24594 | 599-475 | |

| 560 | 4.0-4 | Y112M-4 | 15618-21861 | 473-375 | |

| 12C | 1120 | 75.0-4 | Y280S-4 | 53978-75552 | 2746-2172 |

| 1000 | 45.0-4 | Y225M-4 | 48195-60397 | 2185-1969 | |

| 1000 | 55.0-4 | Y250M-4 | 63953-67457 | 1859-1729 | |

| 900 | 37.0-6 | Y250M-6 | 43375-60712 | 1767-1399 | |

| 800 | 22.0-6 | Y200L-6 | 38556-41973 | 1395-1376 | |

| 800 | 30.0-6 | Y225M-6 | 45391-53966 | 1321-1104 | |

| 710 | 18.5-6 | Y200L-6 | 34218-47895 | 1097-869 | |

| 630 | 15.0-6 | Y180L-6 | 30362-42498 | 863-684 | |

| 560 | 7.5-6 | Y160M-6 | 26989-29381 | 682-673 | |

| 560 | 11.0-6 | Y160L-6 | 31774-37776 | 646-540 | |

| 500 | 7.5-6 | Y160M-6 | 24097-33728 | 543-430 |

外形及安装尺寸示意图 Lnstallation size diagram

| 机 号 | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 进风口尺寸 Air inlet | 出风口尺寸 Vent | |||||||||||||

| NO | D1 | D2 | D3 | 螺栓 | 个数 | A1 | A2 | A3 | A4 | A5 | A6 | a*b | c*d | n1-d1 |

| 2.8 | 282 | 310 | 333 | M6 | 8 | 228 | 259 | 286 | 200 | 228 | 260 | 64*4 | 77*3 | 14-Φ11 |

| 3.2 | 325 | 352 | 370 | M6 | 8 | 255 | 286 | 313 | 218 | 247 | 280 | 74*4 | 84*3 | 14-Φ11 |

| 3.6 | 368 | 387 | 413 | M8 | 16 | 294 | 324 | 352 | 250 | 278 | 310 | 81*4 | 70*4 | 16-Φ11 |

| 4 | 409 | 437 | 460 | M8 | 16 | 329 | 360 | 388 | 285 | 315 | 340 | 72*5 | 79*4 | 18-Φ11 |

| 4.5 | 446 | 492 | 515 | M8 | 16 | 363 | 395 | 422 | 320 | 348 | 380 | 78*5 | 88*4 | 18-Φ11 |

| 5 | 500 | 540 | 565 | M8 | 16 | 405 | 435 | 464 | 356 | 384 | 416 | 109*4 | 97*4 | 18-Φ11 |

| 5.6 | 562 | 593 | 624 | M8 | 16 | 450 | 497 | 531 | 370 | 422 | 485 | 80*6 | 88*5 | 18-Φ11 |

| 6 | 603 | 640 | 660 | M8 | 16 | 483 | 532 | 563 | 427 | 478 | 508 | 106.4*5 | 95.6*5 | 20-Φ11 |

| 6.3 | 640 | 667 | 698 | M8 | 16 | 494 | 542 | 566 | 441 | 485 | 509 | 108*5 | 97*5 | 20-Φ11 |

| 7.1 | 730 | 755 | 795 | M8 | 16 | 568 | 621 | 662 | 497 | 554 | 593 | 125*5 | 110*5 | 20-Φ11 |

| 8 | 810 | 856 | 885 | M10 | 16 | 640 | 700 | 746 | 560 | 625 | 669 | 140*5 | 125*5 | 20-Φ11 |

| 10 | 1000 | 1065 | 1095 | M10 | 16 | 800 | 860 | 906 | 700 | 765 | 809 | 172*5 | 153*5 | 28-Φ12 |

| 机号 | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 外形及安装尺寸 Shape and installation dimensions | |||||||||||||

| Model | G | M | F | N | K | E | L | L1 | L2 | L3 | L4 | L5 | N1-d1 |

| 2.8 | 477 | 600 | 210 | 350 | 197 | 174 | 700 | 470 | 438 | 970 | 898 | 890 | 14-Φ11 |

| 3.2 | 546 | 670 | 236 | 400 | 230 | 195 | 720 | 470 | 438 | 970 | 898 | 890 | 14-Φ11 |

| 3.6 | 599 | 752 | 253 | 450 | 253 | 222 | 760 | 470 | 438 | 970 | 898 | 890 | 16-Φ11 |

| 4 | 680 | 810 | 295 | 500 | 312 | 251 | 828 | 560 | 528 | 1080 | 958 | 990 | 18-Φ11 |

| 4.5 | 756 | 925 | 327 | 570 | 354 | 312 | 865 | 560 | 528 | 1080 | 958 | 990 | 18-Φ11 |

| 5 | 825 | 1040 | 343 | 625 | 354 | 354 | 1018 | 560 | 528 | 1080 | 958 | 990 | 18-Φ11 |

| 5.6 | 916 | 1130 | 384 | 680 | 390 | 394 | 1056 | 560 | 528 | 1080 | 958 | 990 | 18-Φ11 |

| 6 | 980 | 1210 | 408 | 745 | 420 | 385 | 1089 | 640 | 608 | 1080 | 1168 | 1200 | 20-Φ11 |

| 6.3 | 1017 | 1300 | 432 | 790 | 440 | 411 | 1154 | 640 | 608 | 1300 | 1168 | 1200 | 20-Φ11 |

| 7.1 | 1202 | 1450 | 522 | 880 | 798 | 500 | 1307 | 1170 | 1130 | 1730 | 1590 | 1630 | 20-Φ11 |

| 8 | 1286 | 1815 | 582 | 1080 | 565 | 284 | 1556 | 1420 | 1380 | 1780 | 1600 | 1680 | 20-Φ11 |

| 10 | 1589 | 2195 | 687 | 1300 | 700 | 350 | 1656 | 1550 | 1510 | 1880 | 1740 | 1780 | 28-Φ12 |

4-72型-C式叶轮、机壳、进风口、机架、轴承箱等皮带传动而组成。叶轮:由10个后倾斜的机翼型叶片、曲线型前盘和平板后盘组成。并经过动平衡校正,气动性能,故运转平衡、振动小、效率高、寿命长等特点。

4-72型-C式采用不锈钢板焊成蜗型壳体,进风口全部模具成型,风机的传动方式为C式皮带传动。是一款高效率、高性能、低耗能环保风机。具有耐化学腐蚀、不易老化、机械振动小、噪音低、运转平稳等特点。

4-72A\D型在离心通风机的基础上增加方形保温箱体。它在对于输送含有热量气体的场合,能有效减少由进风口到出风口热量的散失,从而确保气体温度的稳定性。

4-72型-A式采用不锈钢板焊成蜗型壳体,进风口全部模具成型,配直连电动机而组成。是一款高效率、高性能、低耗能环保风机。可输送含酸碱成分及化学成分的腐蚀性有毒气体。

品牌:万通星风 品名:4-72-3.6C-1.1Kw不锈钢离心风机 型号:4-72型-C式 简介:采用不锈钢板焊成蜗型壳体,进风口全部模具成型,风机的传动方式为C式皮带传动。是一款高效率、高性能、低耗能环保风机。具有耐化学腐蚀、不易老化、机械振动小、噪音低、运转平稳等特点。